Labelbox services helps research team explore AI-guided defect detection techniques

At Labelbox, we're passionate about empowering the AI community, especially universities and cutting-edge research teams. While we often share updates on our platform and customer stories, we're excited to introduce a new series of blog posts highlighting fascinating research projects leveraging Labelbox.

These posts will delve into how researchers are using Labelbox—both our software and services—to tackle complex data challenges and push the boundaries of AI. Today, we're exploring AI-Guided Defect Detection Techniques to Model Single Crystal Diamond Growth, a study by Rohan Reddy Mekala, Elias Garratt, Matthias Muehle, Arjun Srinivasan, Adam Porter, and Mikael Lindvall.

Research introduction

Researchers recently identified several challenges in producing high-quality single crystal diamonds (SCDs) at scale. Despite extensive development efforts, current manufacturing relies on trial-and-error experimentation, leading to inconsistent results and defects. In order to address these issues, researchers across the United States collaborated to propose new methodologies using machine learning and AI models to predict future diamond growth states for accelerated material development, improved quality, and larger sizes.

The research team focused on these challenges:

- Lack of predictability: Existing techniques currently lack the ability to predict diamond growth states, hindering process control and the potential for correction.

- Issues with scale: Diamond is an essential material for tools in power electronics, health sciences, and engineering, but each field has different requirements in terms of quality, purity, and size. The inability to predict growth subsequently makes it difficult to scale production.

- Ineffective research methodology: Current research methods on developing a method to sustainably and reliably produce high quality diamonds rely on a trial and error method, leading to inconsistent results and defects from each methodology.

From these challenges, researchers identified an opportunity in using machine learning and deep learning algorithms to predict future diamond growth states to shorten the growth cycle, improve prediction accuracy, and enhance crystalline quality.

How Labelbox was used

Labelbox services was used to build the dataset for object detection of the diamond growth-run images. The process began with an initial batch of 100 images, which were reviewed by a team of three material scientists and 15 Alignerrs that were vetted and onboarded through Labelbox Labeling Services.. Alignerrs provide expert, on-demand annotation services and are selected from a network of trained professionals across diverse data domains.

The scientists provided detailed instructions, including explanatory videos and meetings, to guide the labeling process. The labels were then reviewed by the Alignerrs, where predominant occurrences were identified based on a consensus score. Afterward, the material scientists conducted a final review to ensure the accuracy, consistency, and integrity of the data.

Analysis and model-assisted labeling

Model-assisted labeling (MAL) was implemented in order to improve the consistency of data labeling and address potential variability in interpretation of instructions amongst labelers. This involved training a baseline model incrementally using iterative image-annotation pairs from the initial batch. This baseline model was then overlaid on subsequent batches to assist Alignerrs, significantly reducing labeling time and improving accuracy.

With MAL, the time to label each image decreased from 15 minutes to just 2 minutes. Alignerrs were able to correct and refine annotation based on the baseline model’s predictions until a segmentation accuracy threshold of 80% was achieved. Once this threshold was achieved, the model’s overlays were used as a starting point for future batches.

After the minimum number of images were processed, the final set of image-label pairs was passed on for further research and development of the final semantic segmentation and object detection models. Using MAL and this human-in-the-loop workflow, this streamlined annotation process leads to improved efficiency and label quality.

Key findings

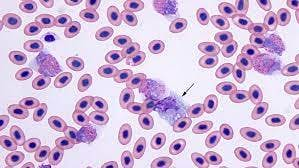

Using object detection and image segmentation algorithms along with the support of a highly-skilled team of Labelbox Alignerrs, researchers were able to create a defect detection pipeline for diamond growth data. This pipeline achieved a high defect classification accuracy with 93.35% for Center-Defects, 92.83% for Poly-crystalline-Defects, and 91.98% for Edge-Defects.

The authors were able to use this pipeline to accurately detect defects, reduce time and costs, and predict future diamond growth.

Working on your own research? Reach out to the team at research@labelbox.com to request a research license or to share your AI research with us.

All posts

All posts