Solutions

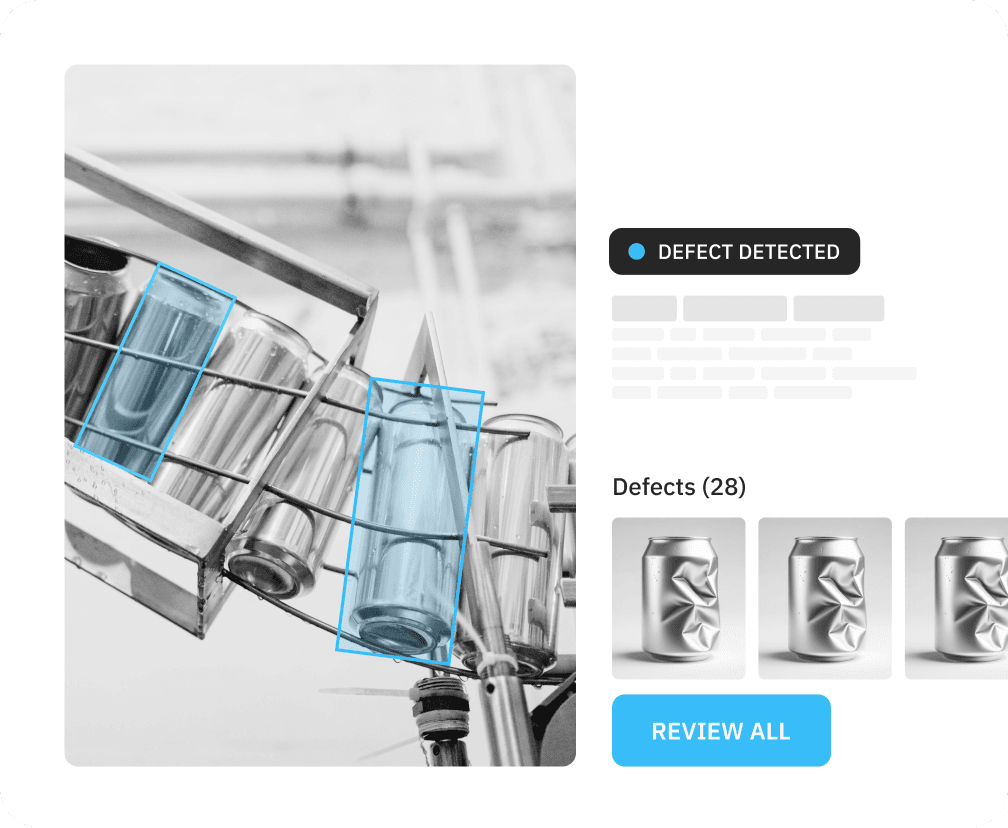

Automate Defect Detection with AI

With AI-powered defect detection, you can now seamlessly integrate the latest advances in foundation models into your product development and QA operations. As the demand for defect-free products continues to rise, it's essential for enterprises to maximize precision and minimize operational and quality-related costs. Labelbox empowers the world’s largest manufacturers to leverage AI solutions tailored to their unique detection challenges.

Customer spotlight

Procter & Gamble (P&G) possesses vast amounts of unstructured data related to their product prototyping, testing, and manufacturing phases. This data, when refined and categorized, becomes essential for training defect detection AI models. To maintain stringent privacy and transparency standards, P&G chose Labelbox to be their data-centric AI platform because of its user-friendliness, compatibility with their existing infrastructure, and robust data security. This allowed them to engage both internal and external labelers, adapt QA processes efficiently, and accelerate model development. Consequently, Labelbox has become a pivotal enterprise-wide solution for defect detection in P&G's global business units.

Boost Quality Control with Intelligent Insights and Proactive Responses

By analyzing high-volumes of images, videos and text, Labelbox provides valuable human-in-the-loop insights for manufacturing processes to ensure product quality, enabling manufacturers to make data-driven decisions that improve customer satisfaction, safety and sales.

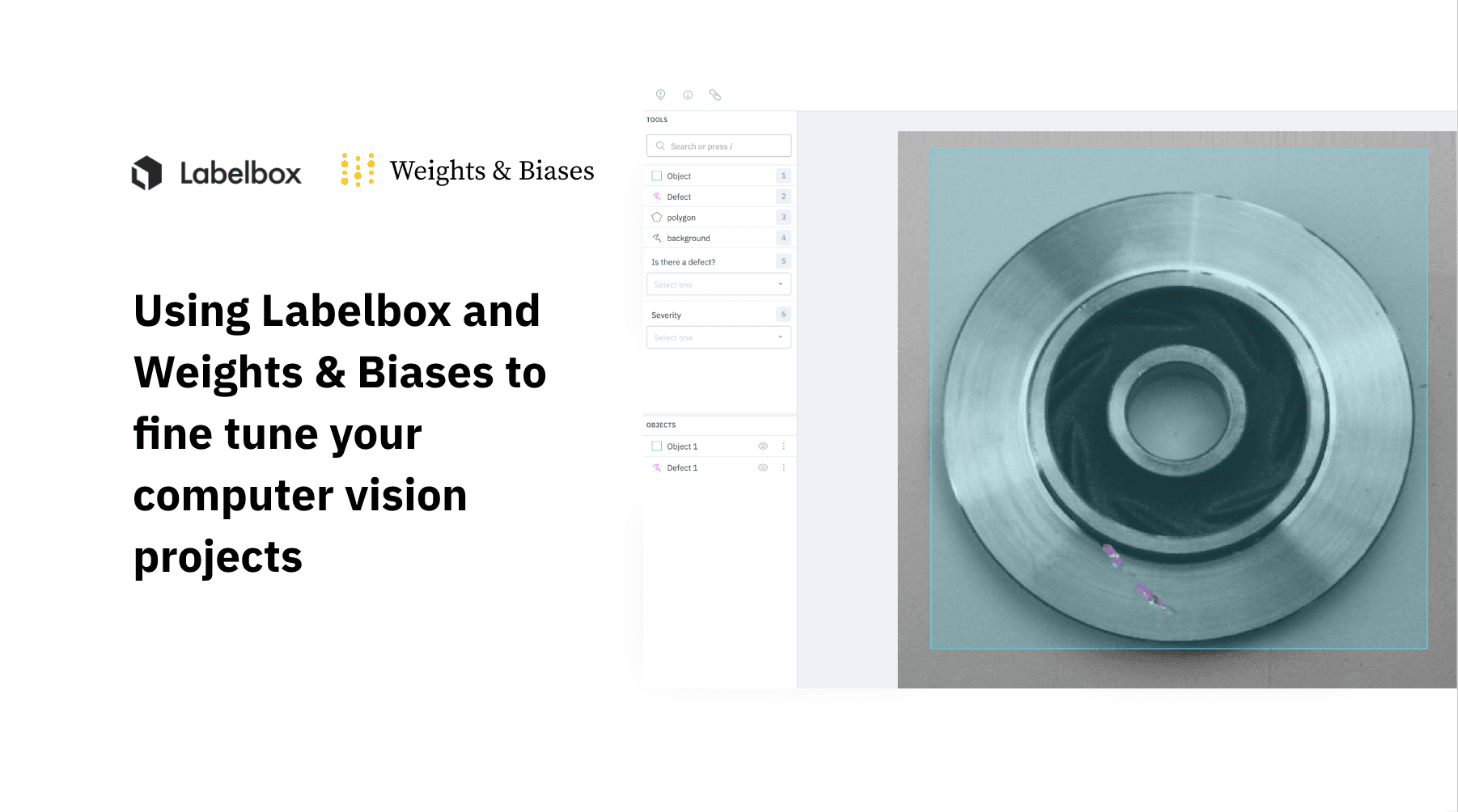

Accelerate model development by 4x

Delivering defect detection AI goes beyond data collection — it's about iterative learning, evaluation, and enhancement. Labelbox provides the environment to train models 4X faster, allowing you to compare models across experiments, diagnose model errors, perform robust error analysis, and drive accurate AI outcomes. Create end-to-end workflows with Databricks and Vertex AI to ensure that your models are aligned with human-centric evaluations, guaranteeing trustworthy outcomes for your defect detection applications.

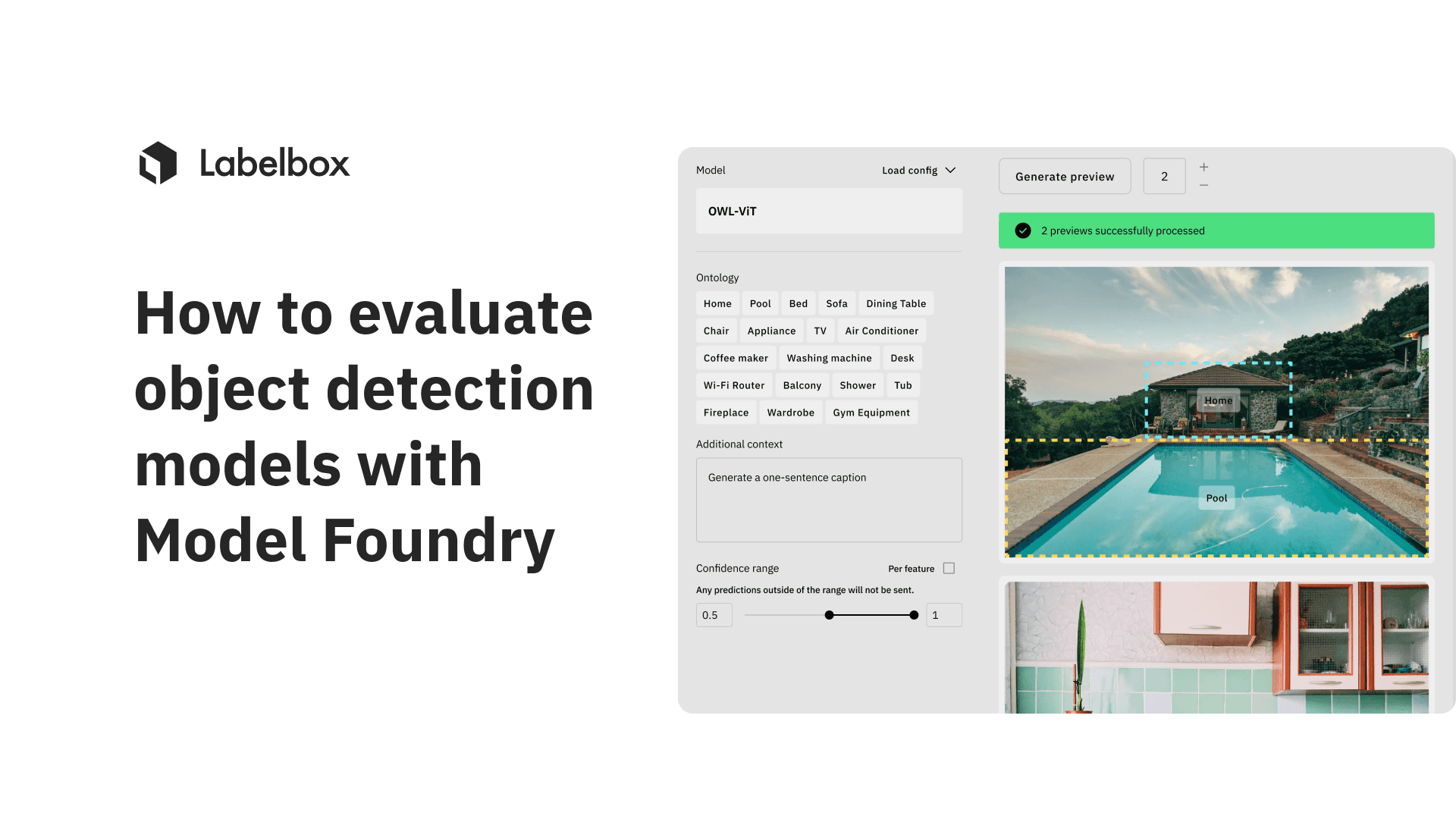

Enrich your data and automate common tasks with foundation models

Automate data labeling and augmentation tasks with Model Foundry. No-code data enrichment with leading closed-source and open-source LLMs at a fraction of the time and cost allows for rapid development of defect detection applications.

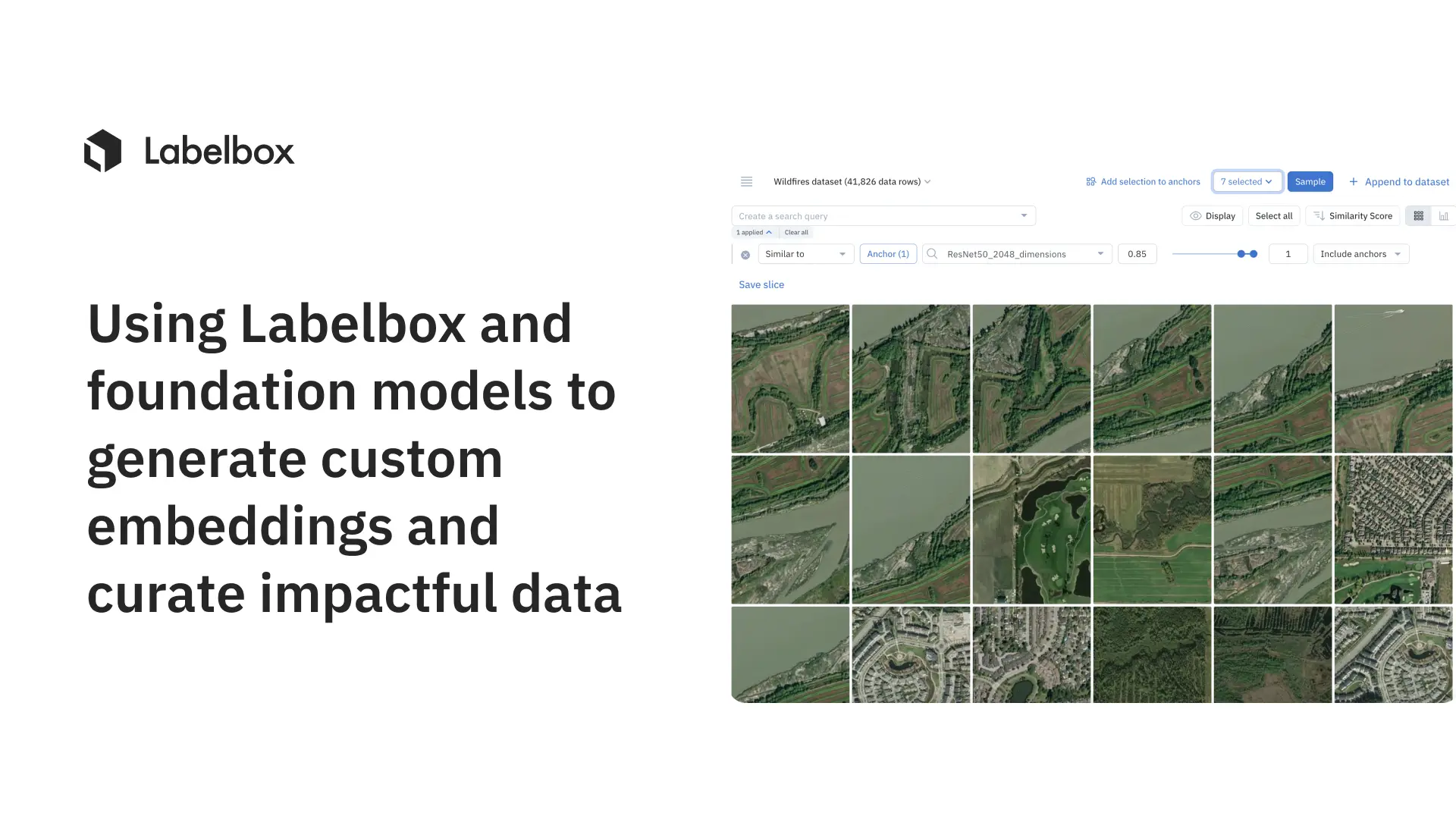

Find edge cases by rapidly curating unstructured data

Catalog eliminates the need to build your own traditional and vector database infrastructure. Build better defect detection models by leveraging out-of-the-box search for images, text, videos, conversations, and documents across metadata, vector embeddings, and annotations.

Improve defect detection with the world’s best data labeling teams

A collaborative human feedback platform to generate perfect data with internal experts and world’s most skillful data labeling services with expertise in computer vision and NLP.

Why Labelbox

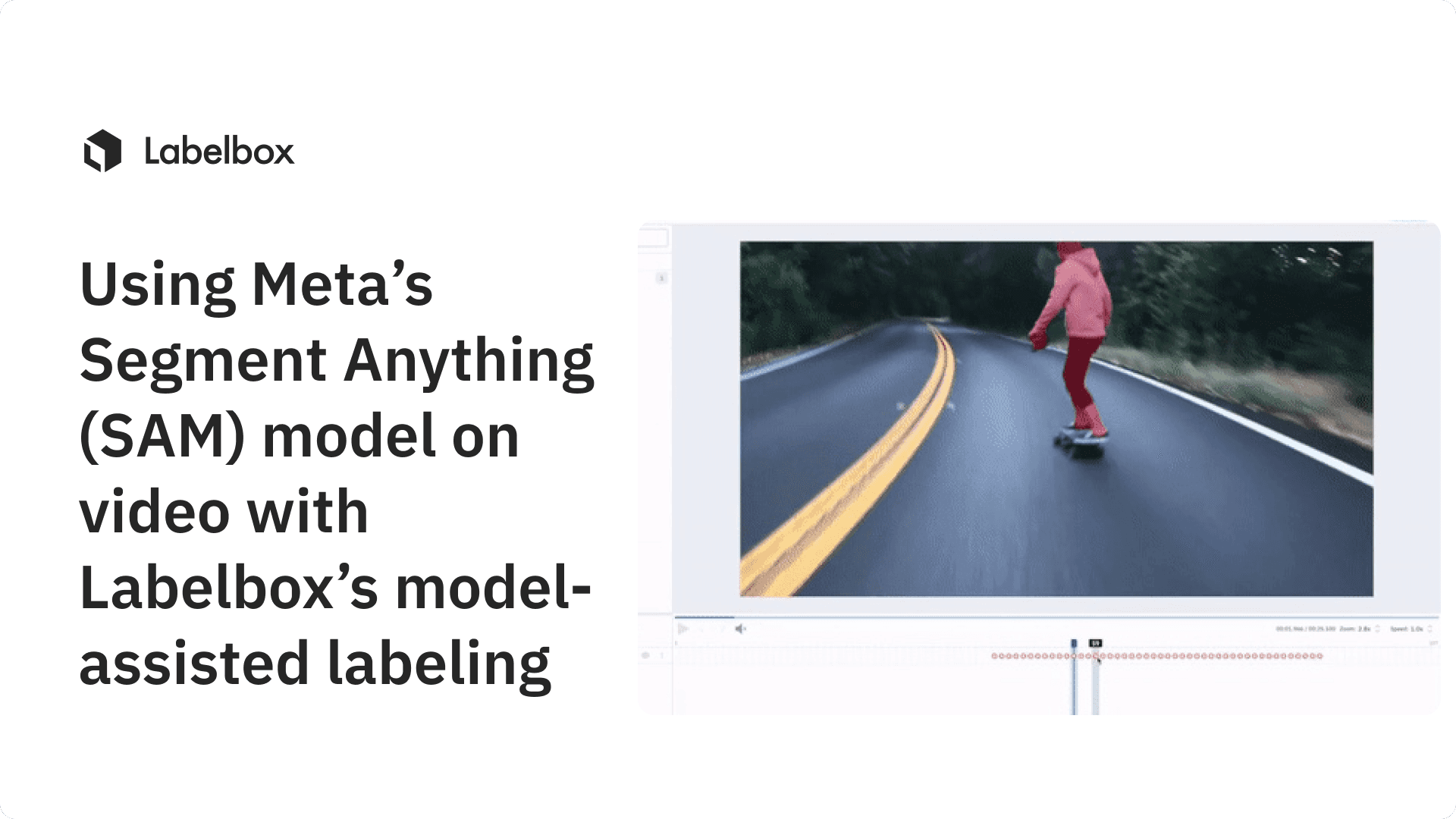

Accelerate AI alignment

Combine model assisted labeling and human expertise to quickly prepare data for training, testing and validation.

Evaluate

Rapidly integrate data, create quality training data, and deploy models to production.

Generate high quality datasets

Optimize custom labeling and review workflows to ensure the highest quality data for model training and fine-tuning.

Maintain data privacy & security

Keep full ownership, transparency, and control over your data throughout the AI development process.